Machine Monitoring Systems

PlantRun is a highly effective and adaptable machine monitoring system. Although designed for automating manufacturing production data collection PlantRun can also be used for capturing any other required parameters or for specialised applications.

Machine monitoring is a broad term that means different things to different people. We have over 30 years expertise in applying software solutions to machine monitoring applications and we will be pleased to discuss your requirement whatever it is.

Connect to any type of machine

PlantRun can connect to any type, make or age of machine or asset. Flexible options allow connection from an existing point on the machine such as a switch, relay sensor, by addition of low cost sensor, communication with PLC, via standard communications and software protocols such as OPC or integration with third party system such as SCADA or ERP, MES.

Scalable from one machine to multi-site system

You can start with PlantRun on a single machine and expand the system to multiple machines, departments or sites, with all data accessible from any location.

Monitoring, control and automation

With PlantRun you are not limited to monitoring and data capture. Any monitored parameters can also be used to provide any level of control and automation.

Peripheral equipment

PlantRun can connect to any existing peripheral equipment for either monitoring to capture data or for control. Typical equipment includes barcode scanners, RFID readers, printers, check weighers but there is no limit to what can be connected.

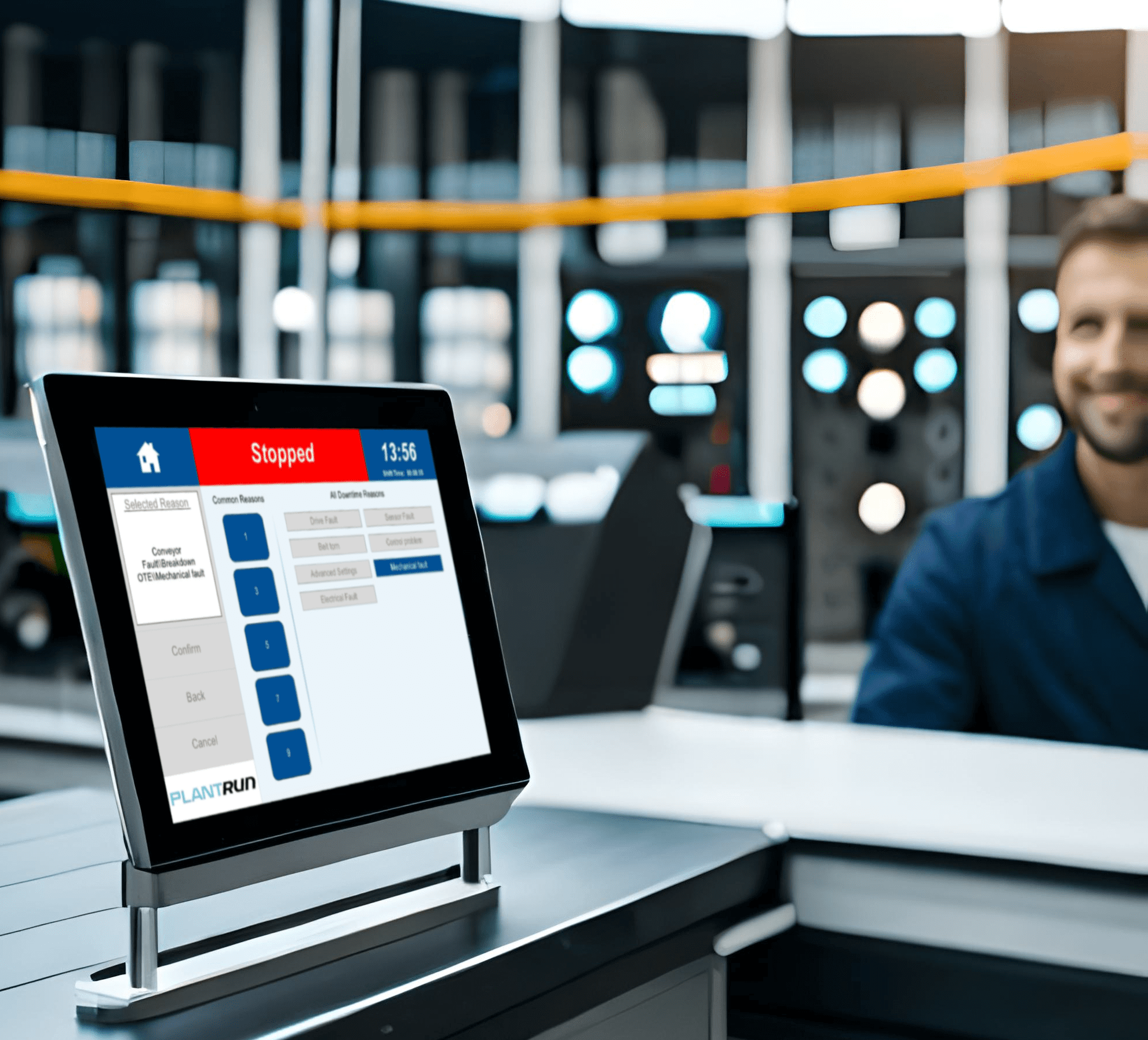

Operator Interfaces

Wherever user or operator interaction is required PlantRun supports a wide range of interfaces. This can include using PC, touch screens, tablets, smart phones, specialised terminals. This may be using your existing hardware or supplied as part of a complete system package.

Accurate live information - eliminates wasteful manual data collection

PlantRun captures and processes data in real time to give you accurate live information. Information becomes available instantly and is accessible on PC’s, tablets, smartphones and large shopfloor displays etc. Automated data capture eliminates wasteful and inaccurate manual data collection and processing.

Reporting and analysis

PlantRun comes as standard with a powerful set of report and analysis tools built in and ready to use. Data can also be exported for use in reporting packages, dashboards or fully integrated with third party systems.

High Data Security

PlantRun is an on-premise system, not cloud based, therefore ensuring the highest data security, which is of paramount importance to many manufacturers especially regulated industries. All your data is under your total control.

Ready to use systems

PlantRun systems are supplied to an agreed specification with all operational information pre-programmed. This means the systems are ready to use from day one with no need for your staff to populate the system. Full training makes any day to day administration straight forward.

High quality technical support

PlantRun users benefit from high quality technical support. Over 85% of users responding to ISO Quality surveys rate our technical support as “Very Good” or “Excellent”. This is one of the reasons why have long standing customers for over 10, 20 and 30 years.

Any questions?

This is just a brief overview of PlantRun capabilities for machine monitoring. If you are looking for functionality not mentioned here or have any questions please ask.

Whatever your machine monitoring requirement contact us for informal advice about how we can help.

Call us on +44 (0) 1642 370666.

To get budgetary pricing for a PlantRun system complete the form below.