Visual Factory Management

Visual factory management is as it suggests the use of visual cues or aids to enable improved management of factories and manufacturing production areas.

PlantRun enables visual factory management in several ways including;

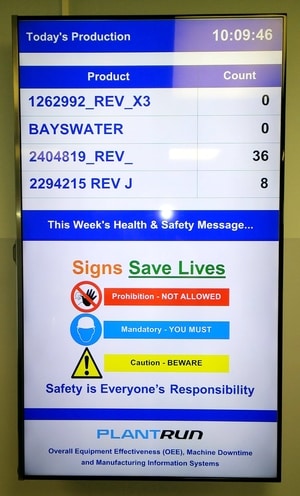

Factory floor information displays

Use PlantRun as a manufacturing display system to inform and motivate staff by displaying production status, OEE and KPI's using large format overhead screens in production, meeting, workshop areas. MS Powerpoint slides and web pages can also be displayed allowing any custom messaging to be shown.

Any number of screens can be driven by PlantRun displaying information relevant to the area, cell or line in which they are sited. These can also provide andon functionality for operators to request assistance etc. PlantRun Display Node hardware makes it straight forward to use any HDMI capable large screen TV, monitor or projector as digital production display boards. Display Node connects to the main system PC server over exisiting networking to generate single static or mutiple scrolling screen displays for highly flexible messaging.

PlantRun Display Node hardware makes it straight forward to use any HDMI capable large screen TV, monitor or projector as digital production display boards. Display Node connects to the main system PC server over exisiting networking to generate single static or mutiple scrolling screen displays for highly flexible messaging.

Health & Safety and Custom Messaging

Display Node enables interactive Health and Safety and custom messages to be displayed alongside live production KPIs. Ready to use packs of health and safety messages are available that automatically changeover each week. Eliminate static health and safety messages that people become 'blind' to. Ready to use images can be easily edited or create your own using MS Powerpoint. Custom messages such as visitor welcome or employee of the month can be also be created and displayed and also website URL's.

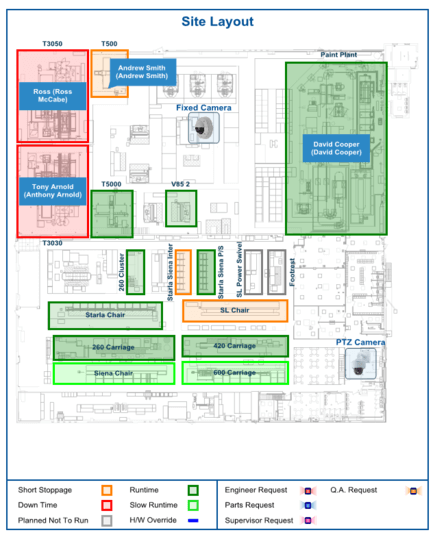

Interactive graphical system displays

A standard feature of PlantRun system is the 'Factory Floor Overview' which is a graphical plan view of the entire production area with the status of each machine or asset color coded. For instance, running assets are represented in green, stopped machines in red (or amber for a short stoppage) , out of service machines in grey and slow running machines in light green.

A quick glance at the screen lets you know the status of all your manufacturing assets. Click on any asset for a detailed representation of that asset and its relevant real-time metrics. Interactive icons on displays can appear when attention is required - for example to prompt when a particular asset requires maintenance.

Typical factory floor overview (17 assets)

Paperless Work Instructions

PlantRun enables paperless or visual work instructions. Any number of files including text, image,audio and video can be stored on the system for easy retrieval. This allows instant access to relevant information such as product assembly diagrams, component lists, standard operating procedures, routine maintenance instructions, machine schematics, emergency contact numbers or procedures, training videos and much more. Files can be accessed from PC, touchscreen and tablet interfaces using on screen buttons or icons or automatically for example when a new product is run.

Controlling IP cameras for real time video capture and replay

PlantRun provides both manual and automated control of IP video cameras. View remote or restricted areas from a central point. Record changeovers or breakdowns for later analysis. Store video of critical processes for traceability etc. Read more about IP camera control using PlantRun.

PlantRun systems are very cost effective with current users reporting typical payback under 12 months. System prices vary depending upon the number of machines monitored and features required. For a fast no obligation budgetary price for a PlantRun system complete the form below.