Machine Downtime Reduction

Reducing equipment or machine down time has an instant beneficial effect on manufacturing operational availability and output. However, without accurate information on the true amount and causes of unplanned downtime it can be difficult to identify how it can be reduced.

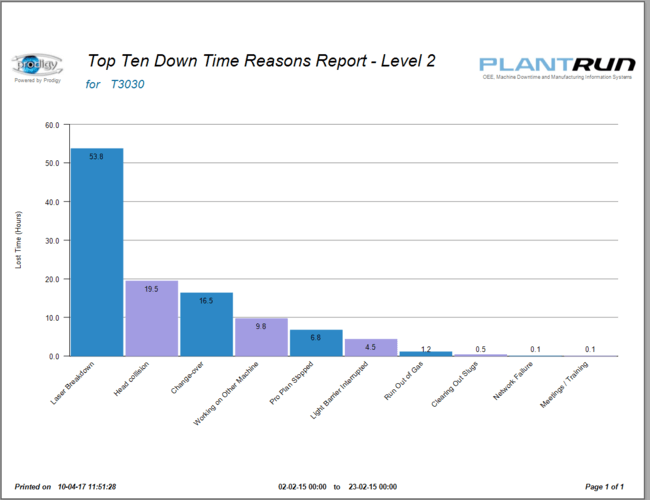

A PlantRun monitoring system that continuously and automatically captures and records machine status provides this information - with downtimes accurate to one second and exact stoppage reasons for every machine. Detailed down time reports, including colour graphs and charts can be produced at any time clearly highlighting where remedial action is needed.

Downtime is often categorised in terms of short or long duration stops….

Short duration stops

Short stops or micro stops are usually where the machine is stopped for the operator to rectify a ‘minor’ problem then restart the machine - typically lasting just a few seconds. Most businesses are unable to accurately quantify short machine stoppage times, as they tend to go unrecorded by operators - who are often too busy and may see them as insignificant.

With a machine monitoring system, all stoppage time is accurately recorded so it is easy to exactly quantify the downtime caused by short stoppages. Although often seen as negligible, accumulated short duration stops can be surprisingly large.

For example just one 15 second short stop every 10 minutes is 12 minutes downtime over an 8 hour shift - a 2.5%loss. Most manufacturers will routinely experience many more short stops than this.

Reducing the causes of short stoppages not only increases efficiency but also eases the burden on operators and results in improved man-machine ratio.

Long duration stops

Identifying the causes of long duration stops is particularly beneficial as focusing attention on these can greatly reduce downtime. To provide accurate information of long stoppages the system not only records downtime but also stoppage reasons.

To do this, machines are usually interlocked after being stopped for a pre-set time and can only be started again once a valid down time reason has been provided.

This ensures that the operator is obliged to enter the reason for the stoppage at the time the stoppage occurs, not at the end of his shift when he may have forgotten or feel tempted to alter the reason to be recorded. In some situations interlocking after the second long stoppage is beneficial and this is available using PlantRun.

The downtime reason is inputted either via the system computer keyboard or a keypad terminal adjacent to the machine. Any number of down time reasons can be selected from a scroll menu on the keypad display. A single keypad can service one or more machines and can also be used for inputting/reading of batch ID and data, production rates etc.

Where machines have 'intelligent' computer or PLC control downtime reasons may be recorded directly without operator intervention. However it is likely that an operator can provide a more accurate downtime reason.

For example a machine PLC may communicate a 'machine jammed' code for a stoppage whereas an operator could identify several causes for the jam. Involving the machine operator in this way also increases their awareness of problems and their resolution.

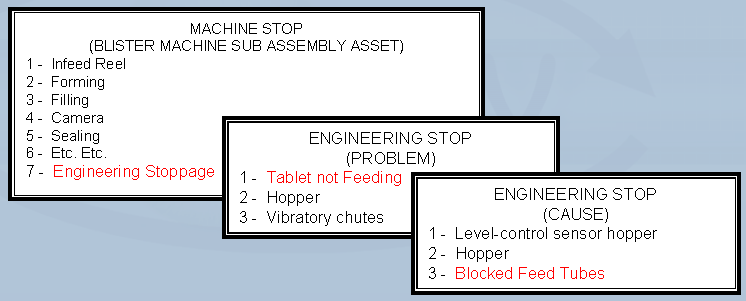

As an example the image below represents a three level downtime reason menu for a blister packing machine.

For this downtime event 'Engineering Stoppage' has been selected at the top level. The next level allows selection of the problem from three possible options for this machine. The third level identifies the cause, also from three options. Downtime can therefore be easily selected from the keypad multi-line menu.

Downtime reasons can also be assigned shortcodes and directly entered via the keyad. This is particularly useful for reasons that need to be entered frequently. When touchscreen interfaces are used downtime reasons can be assigned to on screen buttons.

PlantRun allows multiple sequential reasons to be assigned to a downtime event. Free form text comments can be assigned to any downtime event as an aid to analysis. PlantRun offers a powerful tool set of viewers (dashboards) to allow easy downtime cause analysis, downtime tracking and reporting of downtime to improve machine utilization.

For a fast no obligation budgetary price complete the form below.

Related article; Machine Speed Optimisation