Downtime Cause Analysis

PlantRun is a real-time asset utilisation system and provides sophisticated collection, reporting and analysis of downtime – which is a major cause of lost manufacturing production.

Most manufacturers do not have accurate information about their asset usage. Using manual data collection is not only wasteful of staff time (taken to collect and input data) but is inaccurate (time guesstimates and data inputting errors) and the information you need is not available on demand (time lag from data collection, inputting and processing).

PlantRun enables detailed downtime cause analysis and gives you the information needed to manage effectively and slash downtime and lost production.

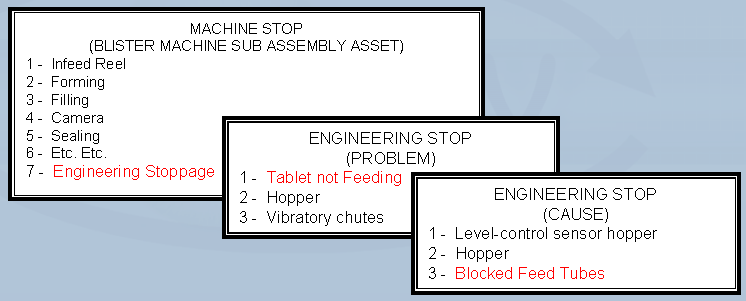

Unlimited downtime causes can be assigned to form a multi level tree structure of reasons for each machine, line or cell. The top level normally includes the generic reason – electrical, mechanical, hydraulic, changeover etc. Each level below that provides options and sub options to define the downtime reason in detail.

The asset operator selects the relevant reason for any downtime from the list using the interface linked to that machine (or by entering a numerical short code). PlantRun can also accept downtime reason codes from a machine PLC, however operator selected reasons generally provide more specific information as to the actual cause of the stoppage.

Downtime dashboards allow you to view and analyse downtime and the causes for it, making downtime cause analysis very easy. This can be done for each machine or asset or across several or all assets making it simple to do a broad or detailed downtime cause analysis.

A quick statistics tool highlights the major causes of downtime over any period you select so you know where to target resources for best results. Tracking changes over time you can see what effect the initiatives you put in place have had on machine utilisation.

To get budgetary pricing for a PlantRun system complete the form below.